Search This Supplers Products:Plastic moldPlastic injection moldingPlastic paving gridplastic palletsports flooring

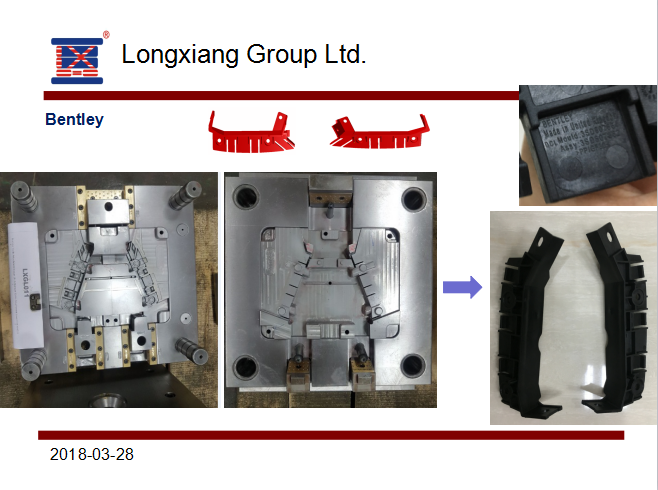

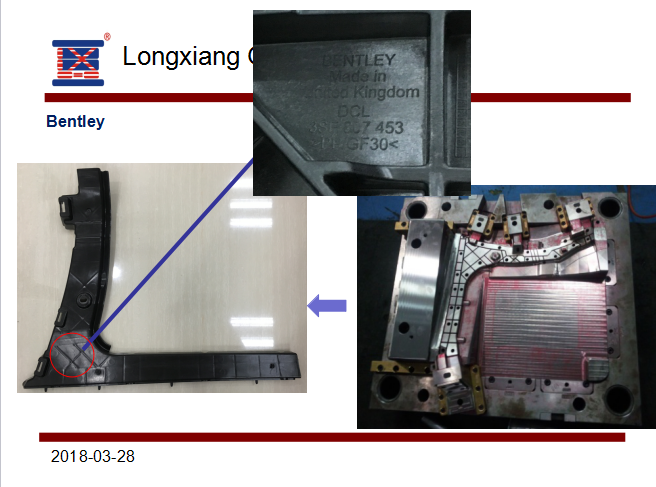

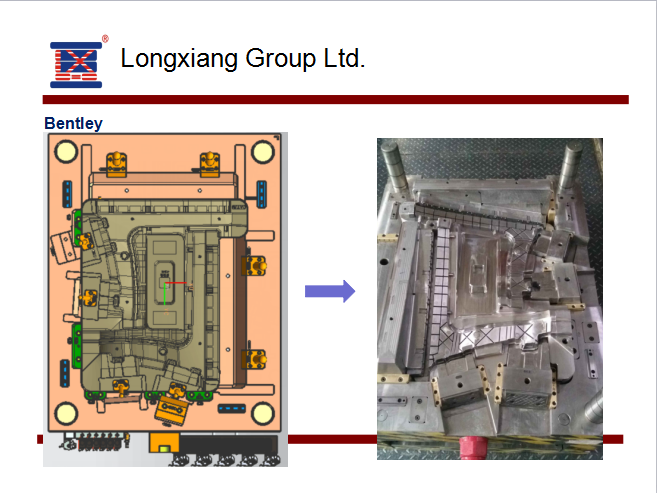

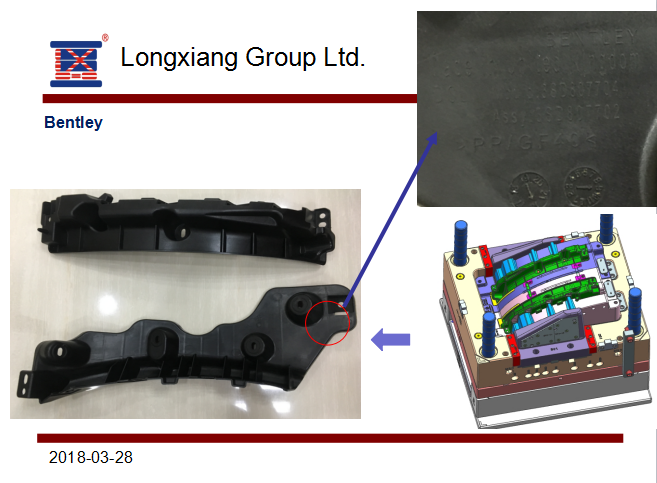

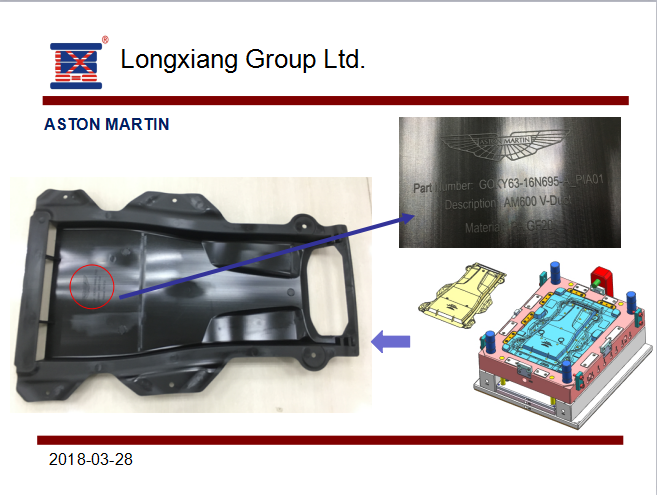

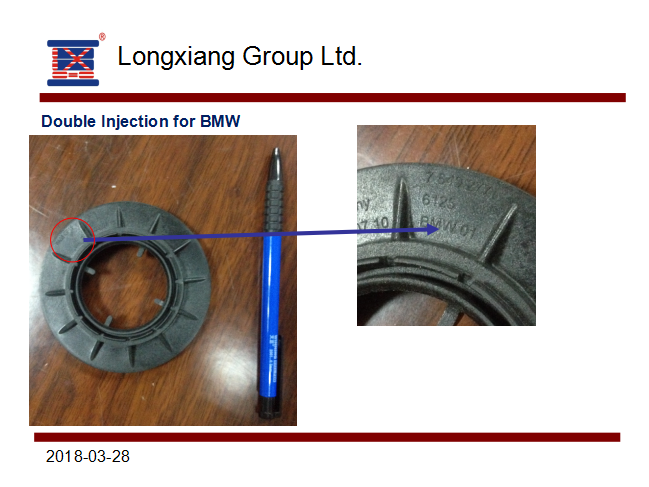

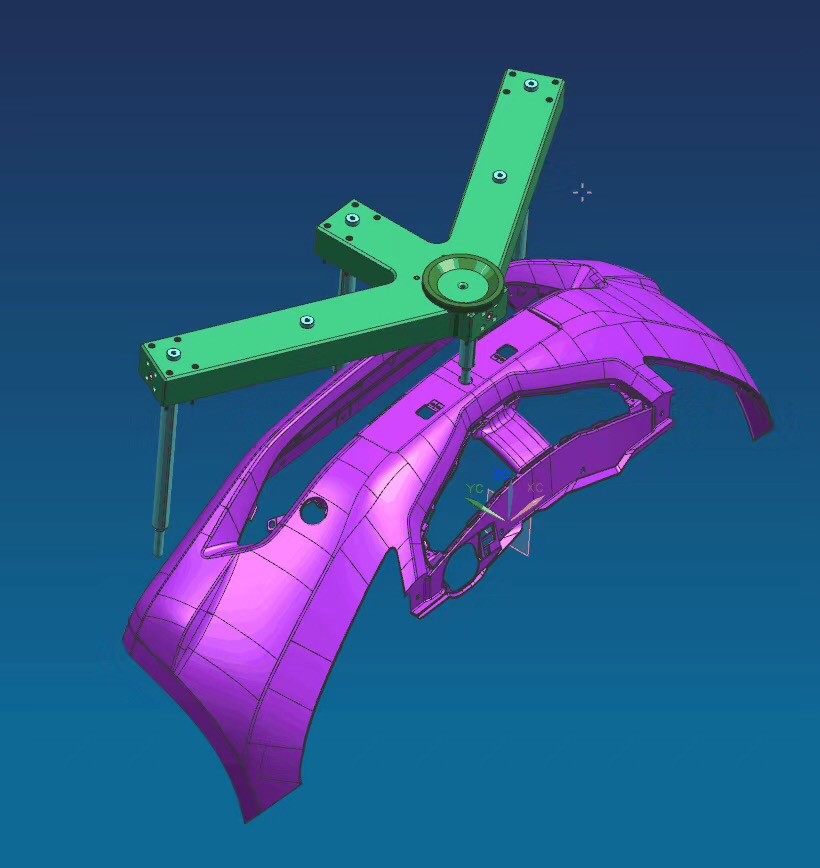

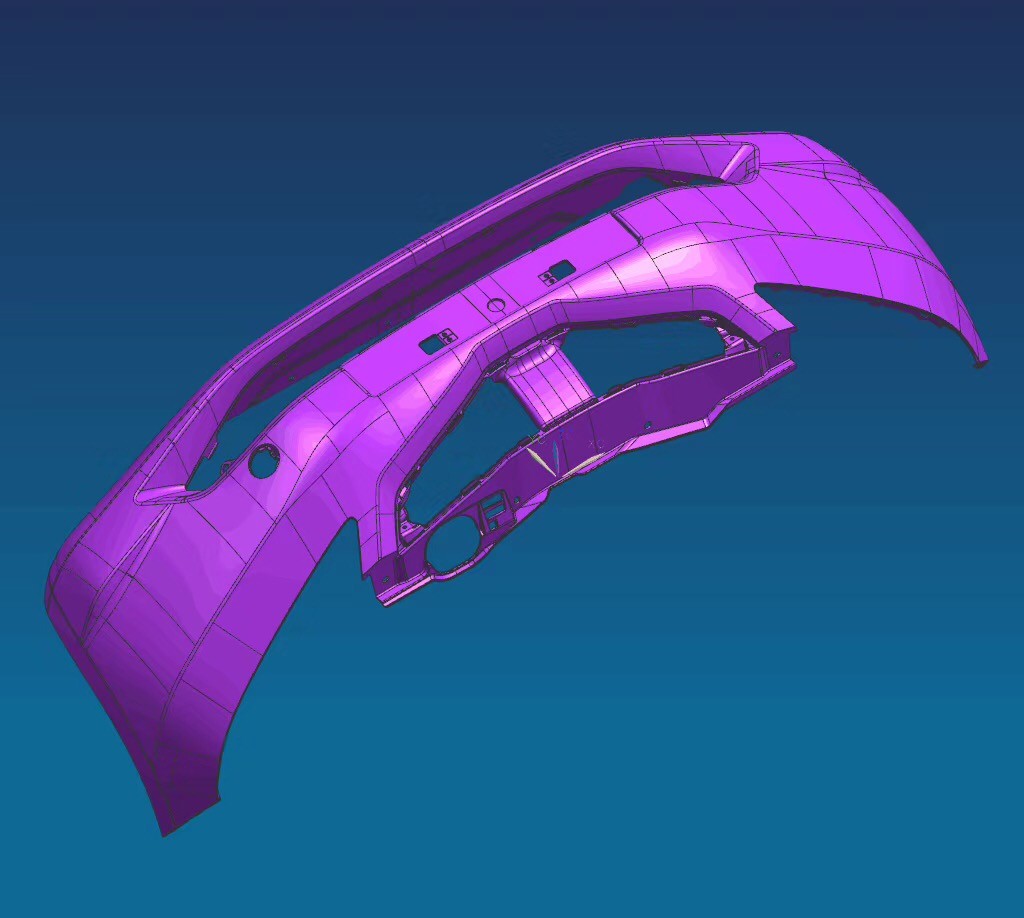

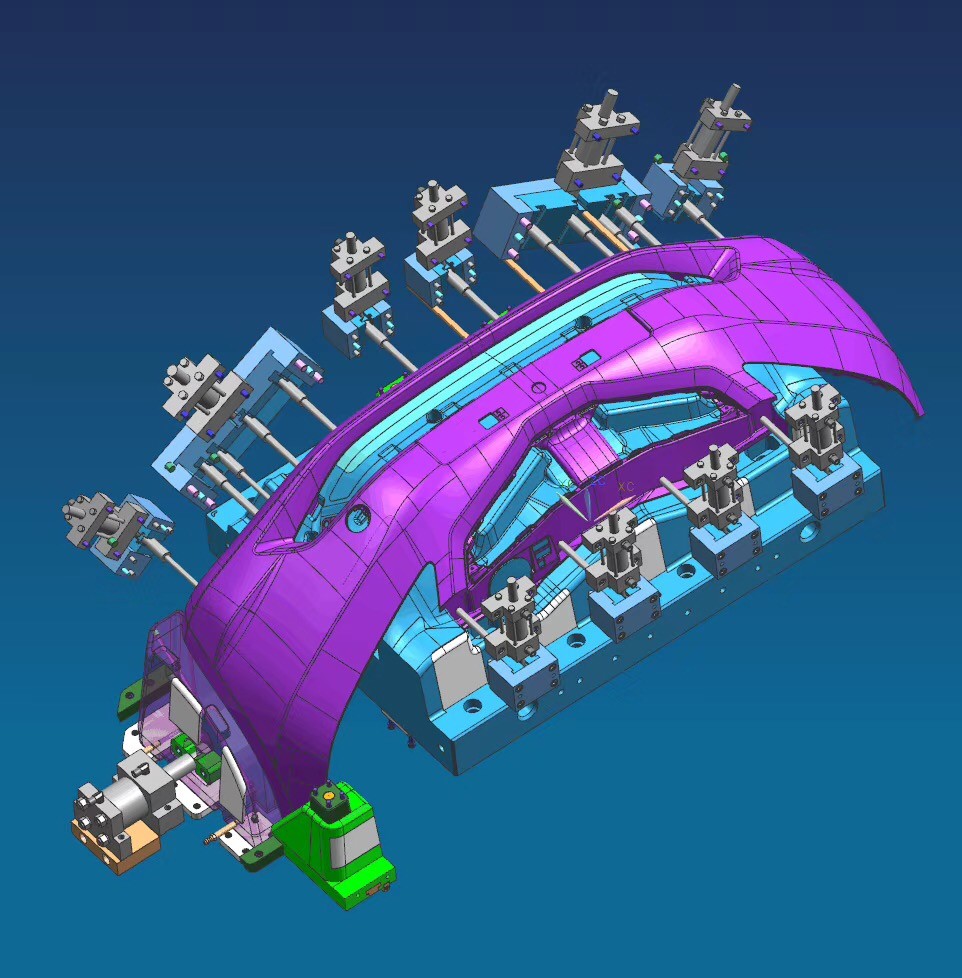

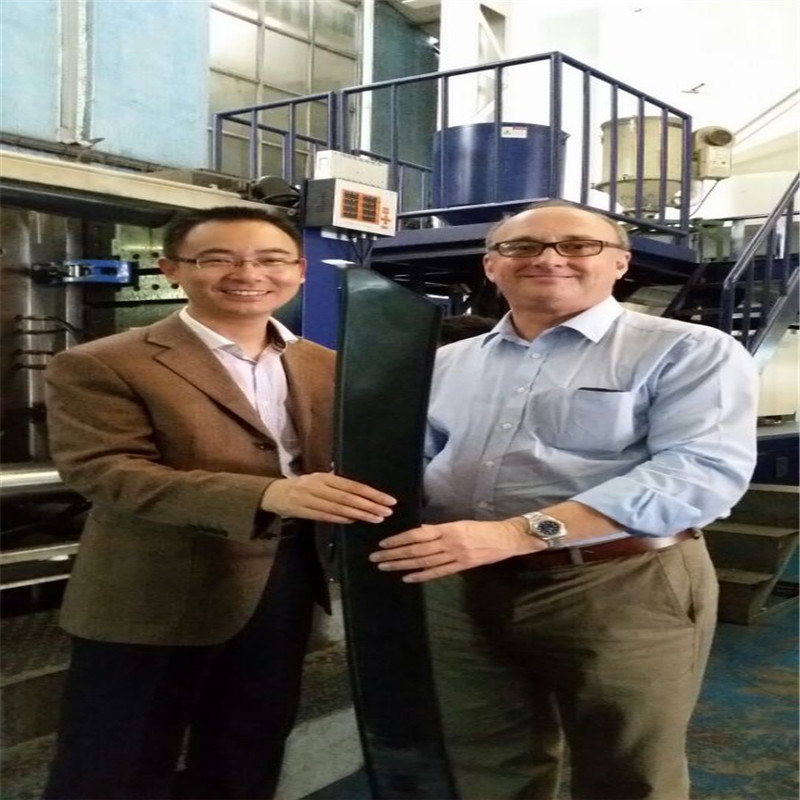

Plastic mould maker of auto spare parts

- group name

- Automotive Component Molds

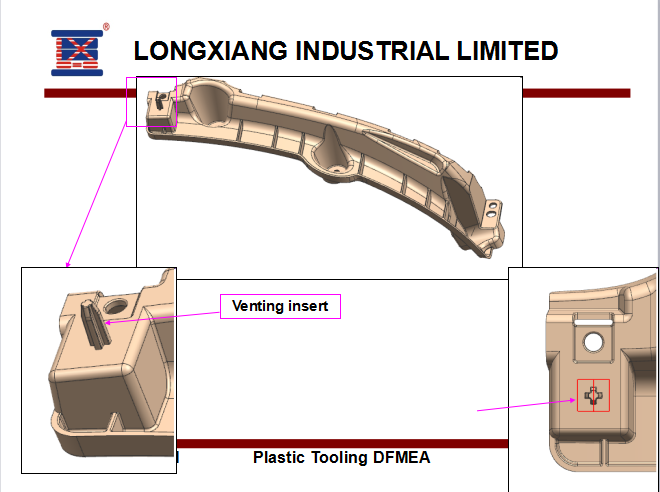

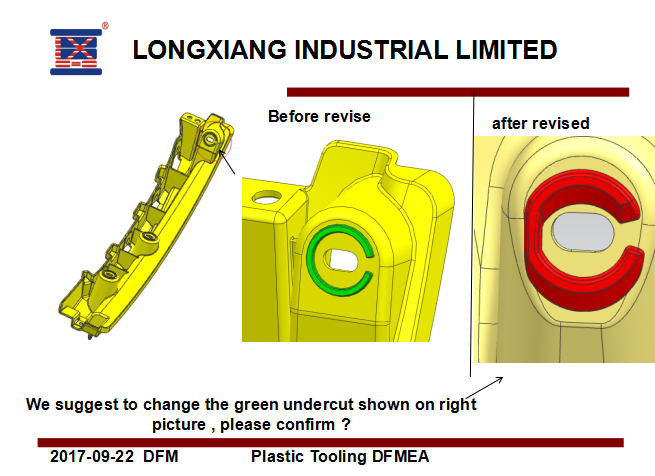

- Min Order

- 1 set

- brand name

- Longxiang Plastic Mold

- model

- LX-A00017

- Nearest port for product export

- Guangzhou, Shenzhen

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, PayPal

- update time

- Fri, 04 May 2018 09:51:11 GMT

Paramtents

Products name Plastic Auto mold maker

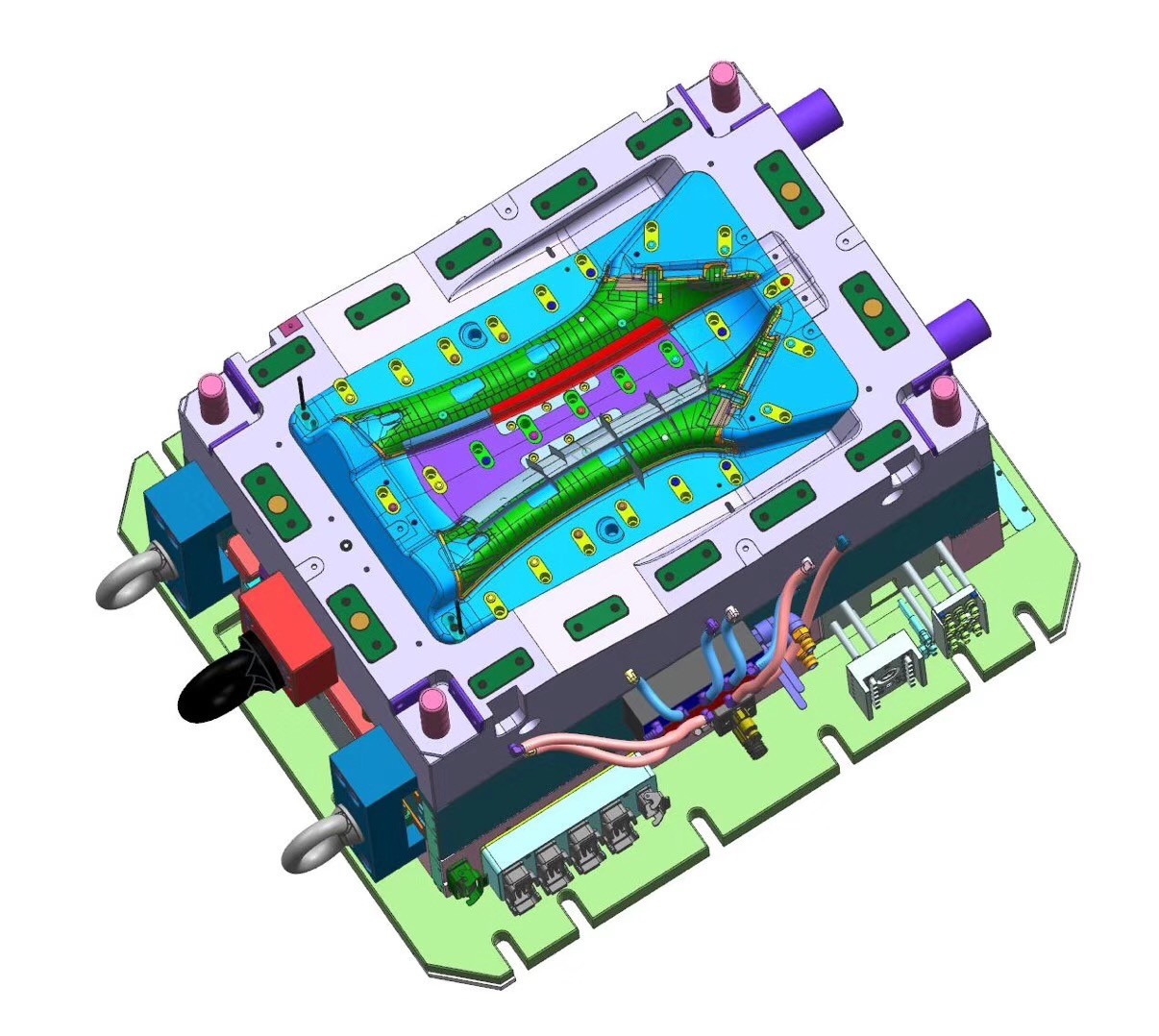

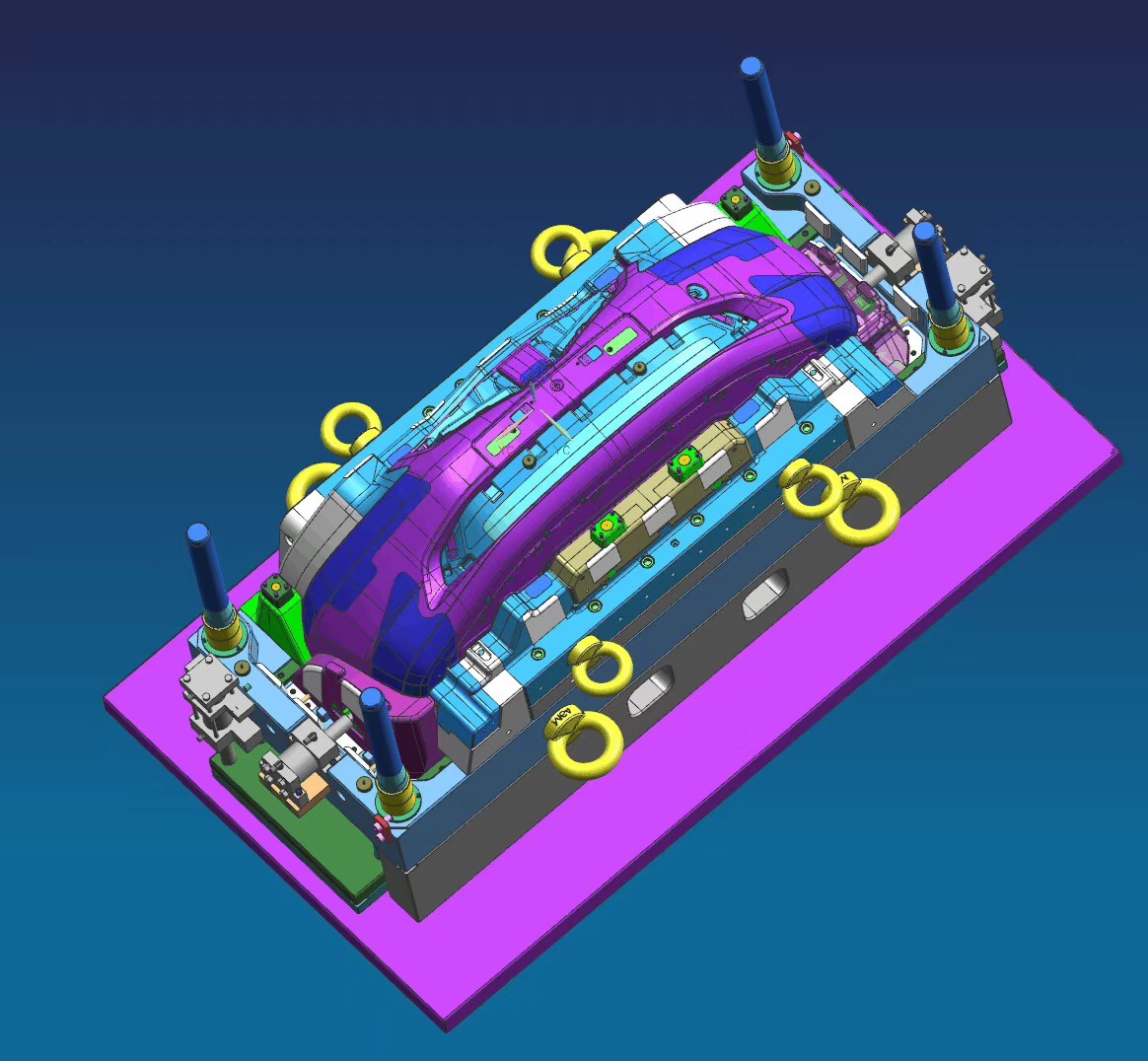

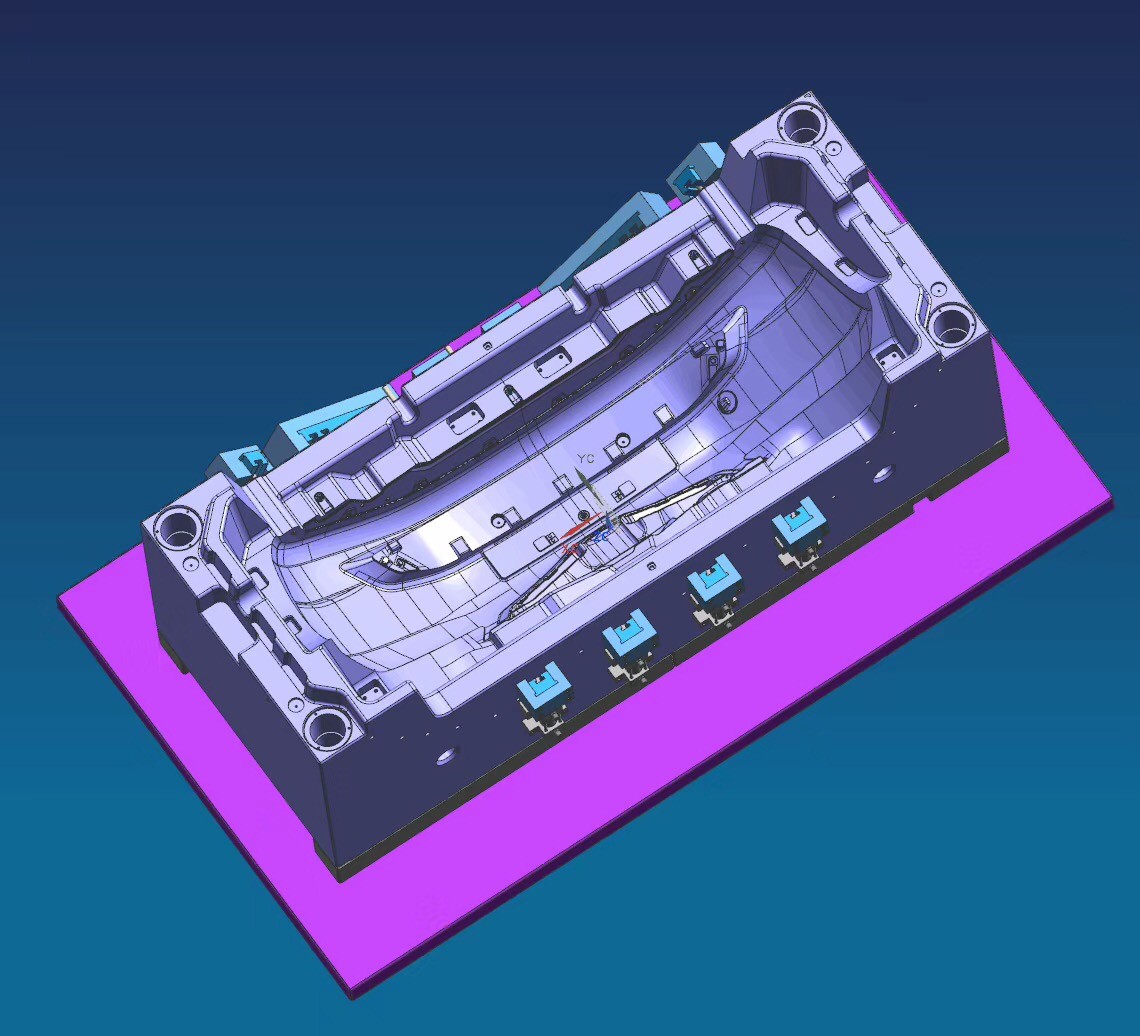

Mold Type Plastic injection mold

Mold Material 45#,P20 steel, 718, 2738, H13, NAK80, 2344, 2343, S136, etc .

Design software CAD

Mould Standard HASCO, DME, MISUMI, JIS, LKM, etc.

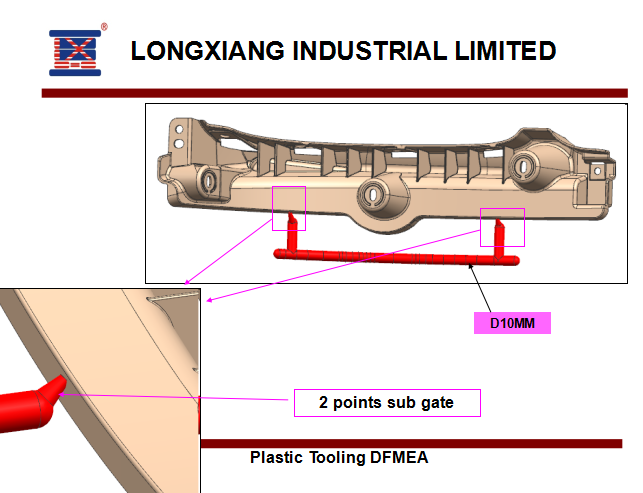

Gate type Side Gate, Sub Gate, Direct Gate, Hook Gate, Pin Point Gate, etc.

Runner type Cold Runner or Hot Runner

Cavity both single and multi cavities available

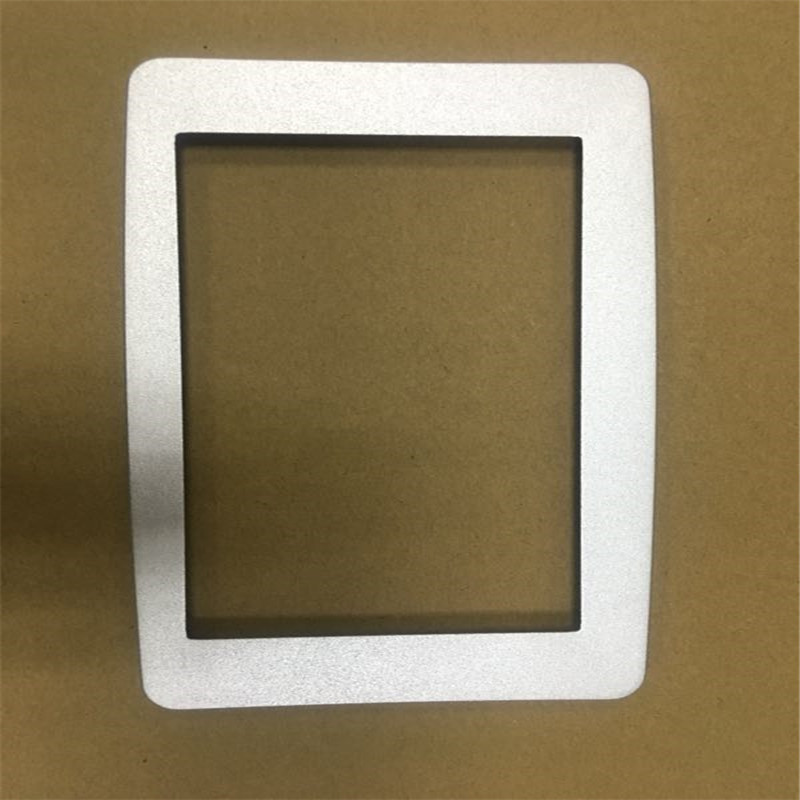

Suface treatment Polish, Etched, Texture, Heat treatment and Nitriding

Mold life 45#:50,000 to 100,000 shots;718: 200,000 to 300,000 shots.H13: 300,000 to 500,000 shots

Packging & Delivery

-

Min Order1 set

Briefing

Detailed

Mold Material | 45#,P20 steel, 718, 2738, H13, |

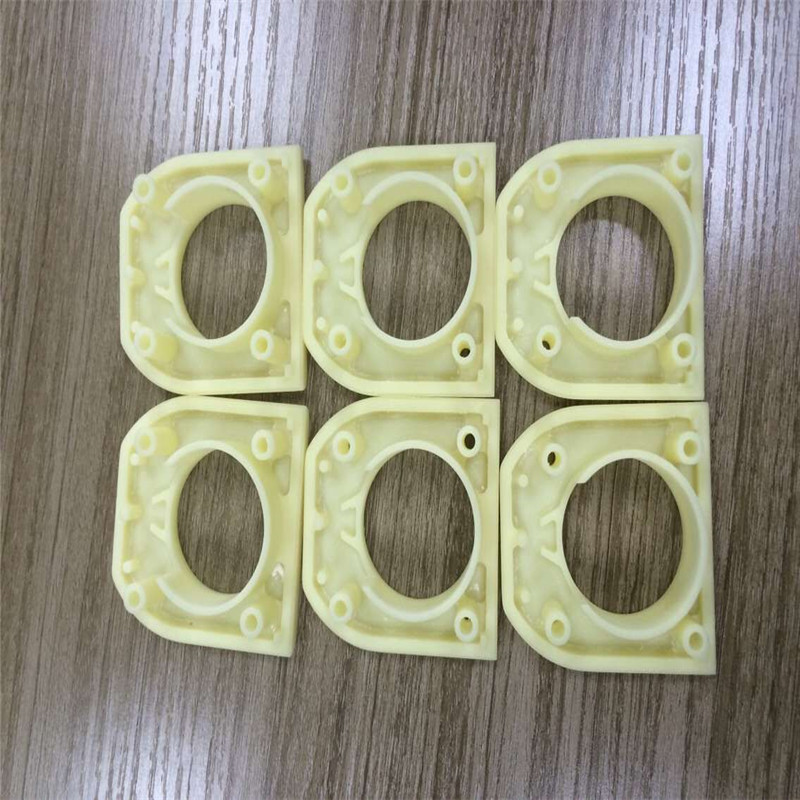

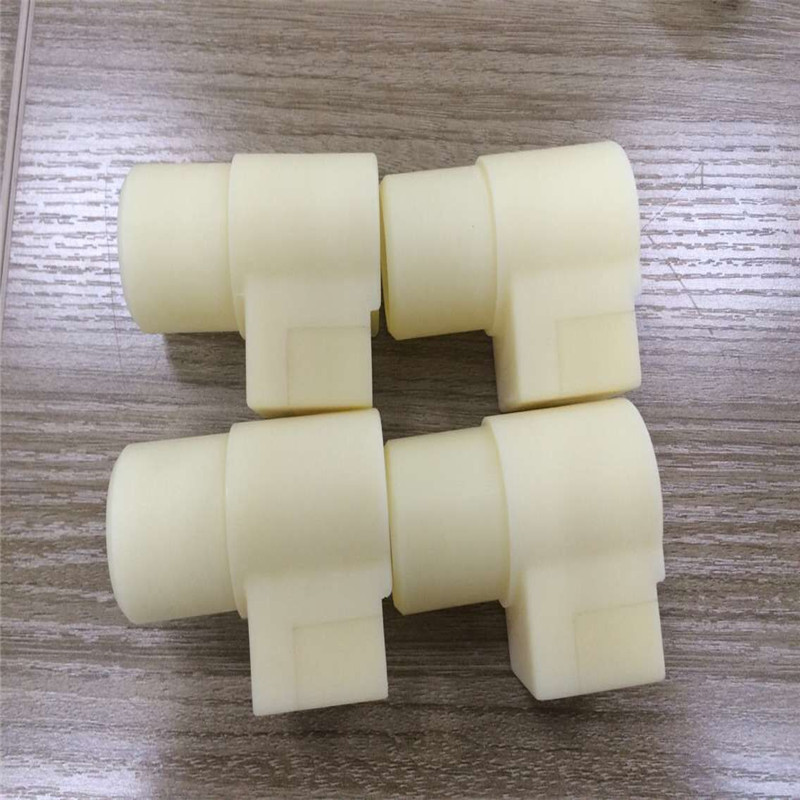

Mold Type | Plastic Injection Molding |

Product Material | ABS,PA,PA66+GF,POM,PC,PP,PET,TPE,PVC,HDPE, PMMA, PU, PAG,etc |

Mold Standard | HASCO, DME, MISUMI, JIS, LKM, etc. |

Mold Tooling Equipment | Lathe,Milling,Grinder,Drill,CNC,EDM, |

Injection Mold Machine | 80T to 2800T |

Product Weight | 50-20000g |

GateType | Side Gate, Sub Gate, Direct Gate, |

Runner Type | Cold Runner or Hot Runner |

Cavity | Single or Multi cavities |

Treatment | Heat treatment and Nitriding,polish ect. |

Mold Life | 45#:50,000 to 100,000 shots |

P20:100,000 to 200,000 shots | |

718: 200,000 to 300,000 shots | |

H13: 300,000 to 500,000 shots | |

Lead Time | Generally mold making will take around 30 days |

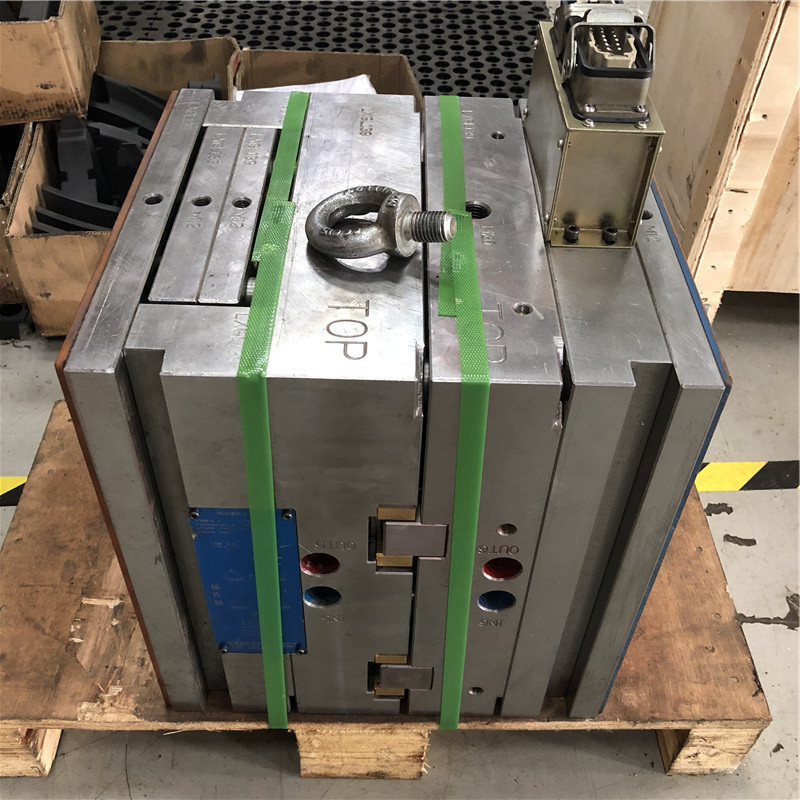

Package | Wooden packing box for molds |

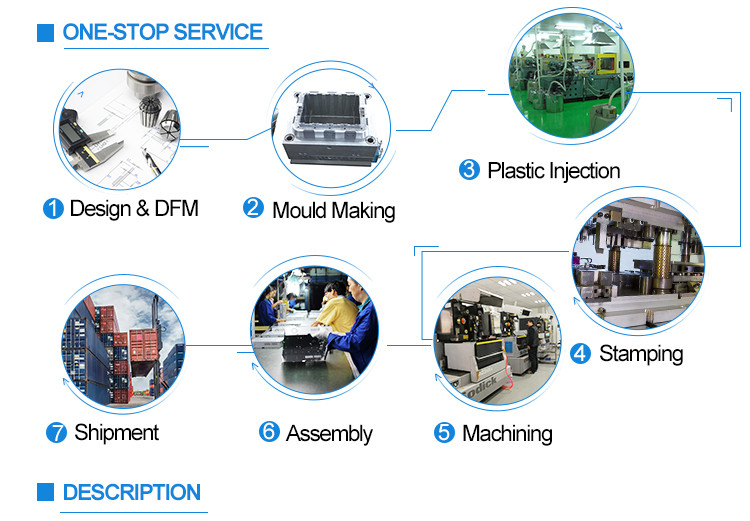

Tooling Developing Procedure:

1.Quotation: We need your require clearly

2.Negotiation: Material, cavity, price, delivery time, payment term, etc.

3.Order: According your own design or choice our design

4.DFMEA: Deign failure mold & Effect analysis to reduce risk

5.Mold design: 2D/3D drawing

6.Cutting Tooling Notice: After customer approve the mould design will start making mould

7.Weekly Report: We will update the mold schedule every week

8.Sample Confirm: Send you sample for conform it, if not satisfied by customer. We modify mould.

9.Delivery Mold: Delivery mould after customer approve sample and arrange shipment.