Search This Supplers Products:Plastic moldPlastic injection moldingPlastic paving gridplastic palletsports flooring

DFMEA

DFMEA

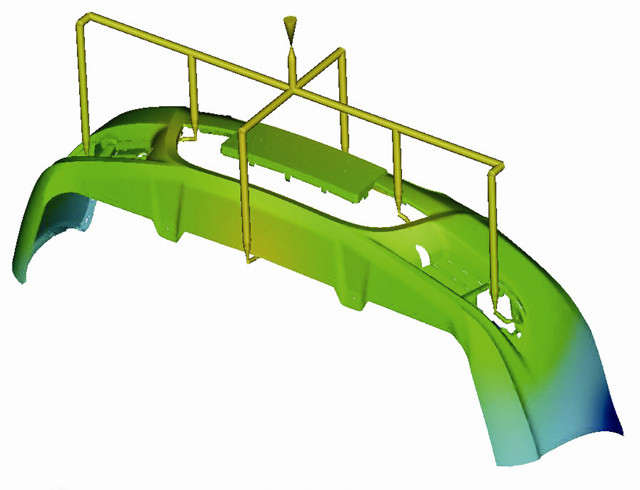

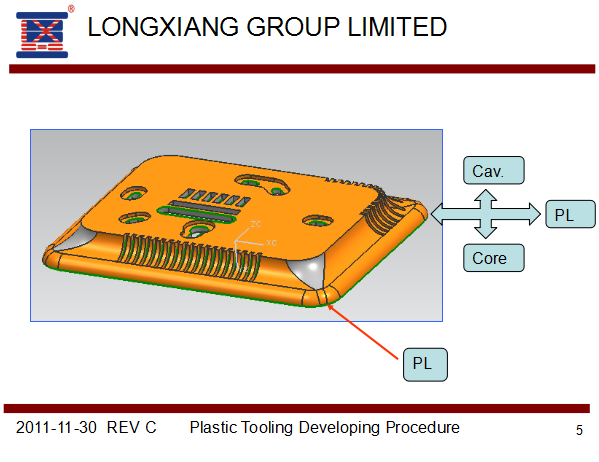

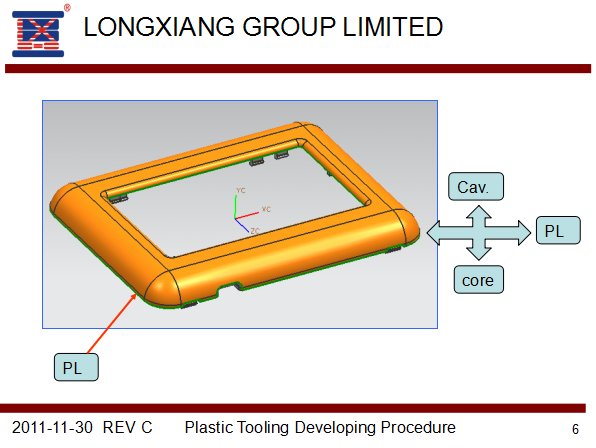

Design Failure Mode & Effect Analysis should be prepared before the 2D tooling design ,which should include P/L, Gate location, Ejector pins and the basic structure of tooling as well as the comments for any parts design defects. This is a good way to save much time and cost for tooling design and fabrication.

When you submit a quote for plastic injection molding we will provide you a detailed report that provides you important information about the design of your custom parts and highlights any potential problematic areas.

Injection molded plastic parts just got a whole lot easier.

1. Minimize Tooling Costs

2. Reduce Design Changes

3. Expedite the Manufacturing Process

4. Ensure Better Part Quality

Our DFMEA will show you the belowing things:

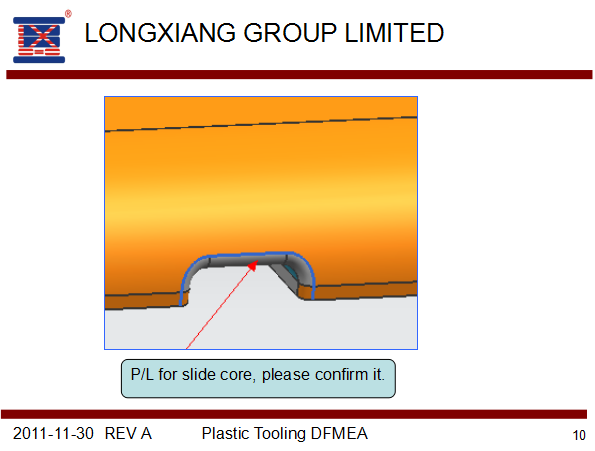

PL

PL

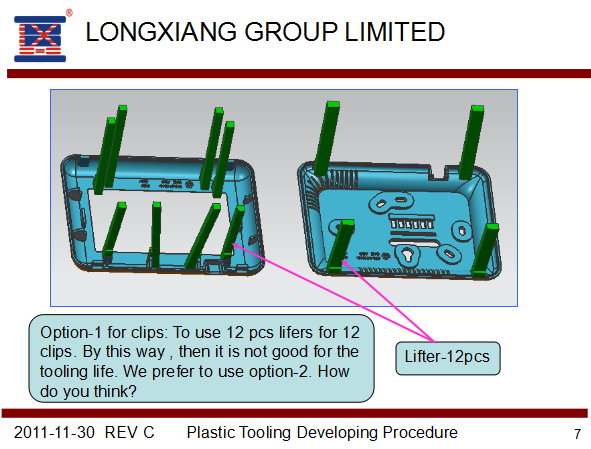

Lifter

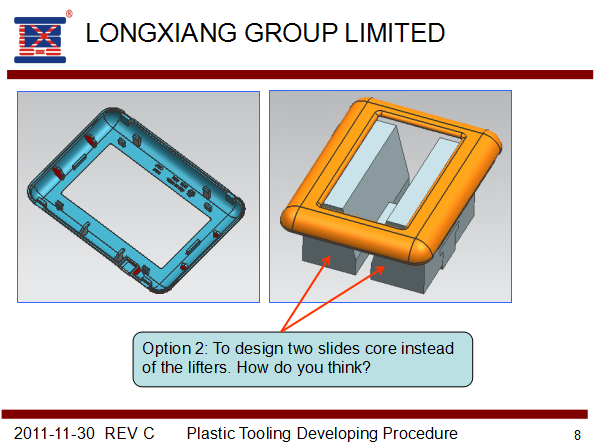

Give you good suggestions

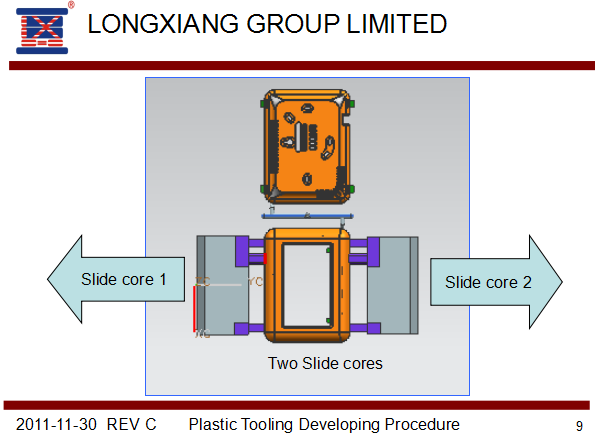

Slide

Slide

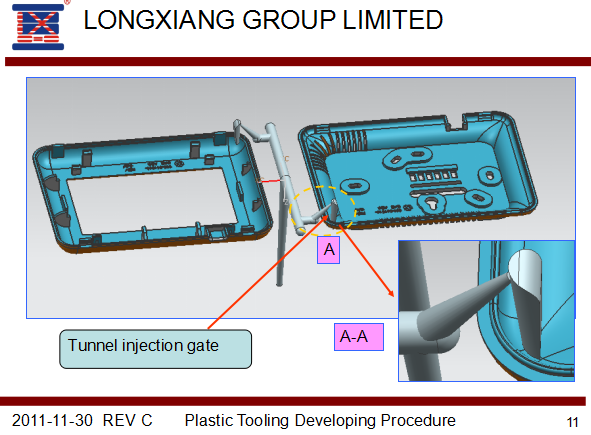

Gate Location

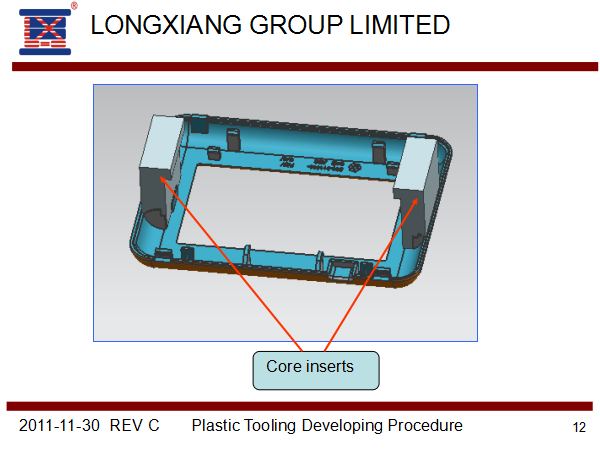

Inserts

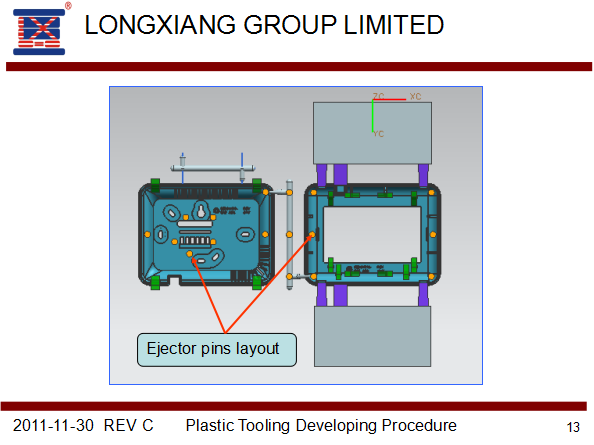

Ejector System

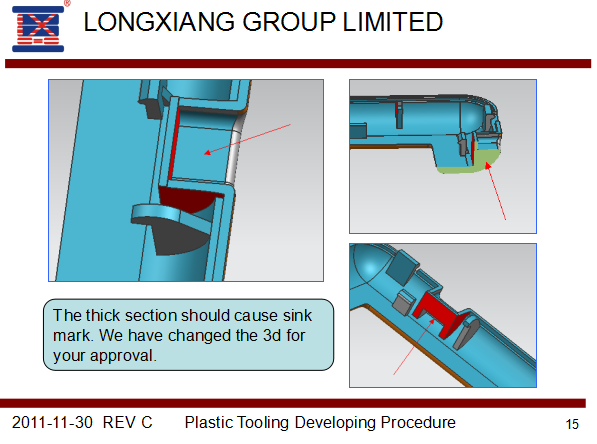

Shrink

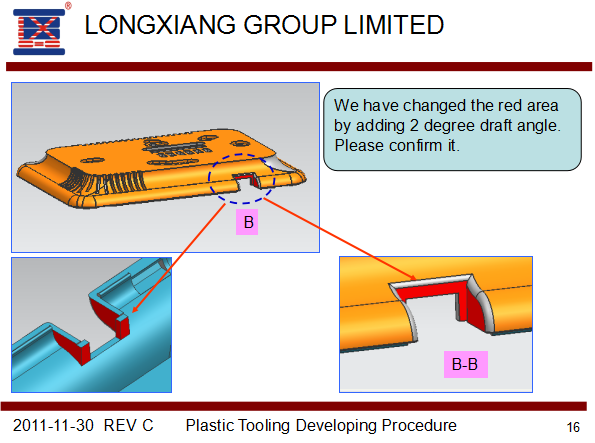

Draft Anagle

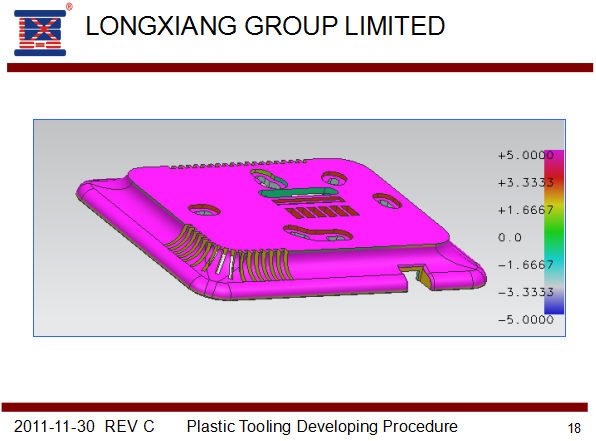

Thickness Analysis